After the security seals are produced and formed, there is another production process, which is printing. printing LOGO, trademark, barcode, or QR code. In order to highlight the recognition of your brand or product, improve impression, or facilitate storage and management, corresponding logos or numbers need to be printed on the security seals.

Currently, there are two commonly used methods for printing trademarks, namely Laser printing and Hot stamping. Which printing method do you want to use to print your trademark LOGO or barcode on the anti-counterfeiting seals?

At this time, you need to understand Laser printing and Hot stamping, and then decide which printing method is more reasonable based on your product design needs and different colors.

So what are the differences between Laser printing and Hot stamping?

Please see below, we have summarized 6 differences based on the production process.

1.Different Printing Conditions

For Laser Marking, the prerequisite is to add laser powder to the security seal’s raw material, otherwise, it will not be marked,

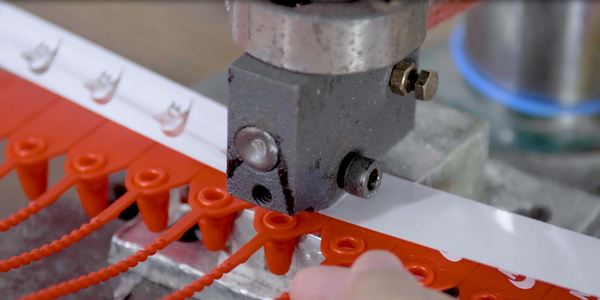

but Hot Stamping does not require it. Hot Stamping requires opening a typeface mold (letter mold or number mold).

2. The Printed Colors are Different

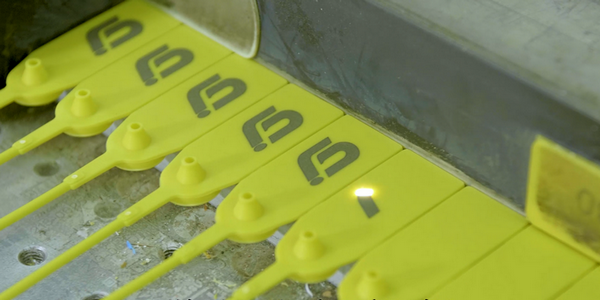

Laser Marking usually produces black color logo marks on the security seals (such as red security seals, white security seals, yellow security seals, blue security seals, green security seals, or other colors of security seals, except black security seals), black security seals use Laser Printing, which will print out white color marks.

and The hot stamping will be the opposite, the loge marks are usually in white color.

3. Printing Effects are Different

The text printed by Laser Marking cannot be touched, Touch the LOGO surface of the security seal, can not be felt, it is a smooth fusion on the surface of security seals.

and the Hot Stamping is concave. Touch the LOGO surface of the security seals, and feel that there is a concave feel.

4. Marking Size and Modification

The size of the Laser marked numbers, letters, and logos can be changed according to customer requirements.

Hot Stamping has a fixed size (once the typeface mold is made, it cannot be changed), so before bulk production must make sure the Printing way.

5. Digital Mark Printing

Laser Marking can print serial numbers from 0 to 9.

Hot Stamping serial numbers are usually printed with seven digits. Generally, 5, 6, 7, and 8 digits can be printed. one more Hot Stamping generally does not have a barcode printing.

6. Laser Printing is more flexible. After designing directly on the computer, you can print trademarks, text, numbers, barcodes, and QR codes without additional design fees.

Hot stamping is relatively fixed. Once the typeface mold is made, the logo size and text size cannot be changed.

Opening typeface mold also requires additional mold costs.

Customers can choose the printing method they need according to their product design needs, which is more reasonable.

Be sure to communicate with sales personnel before making samples or large quantities to avoid mistakes.